Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2025-03-10

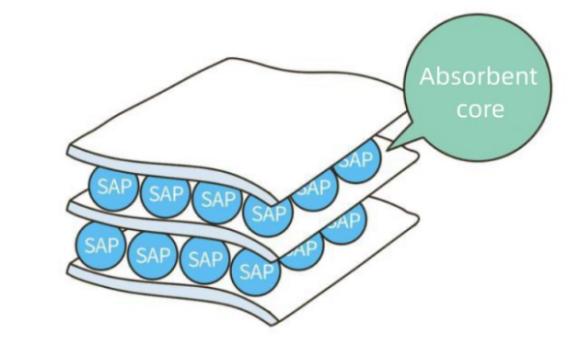

I believe that customers who have customized diapers know that the core part of diapers is the "core", which determines the diaper's absorption capacity, absorption speed, water-locking ability, and whether it is broken. It can be said that the quality of the core directly determines the diaper. The quality of performance also directly determines whether the diaper is a mid-to-high-end product, and its importance is evident.

The absorbent layer of the first generation of diapers is mainly pulp&SAP core, which has a large proportion of fluff pulp and very limited absorption capacity. Moreover, the diaper itself is relatively thick and airtight. It is used in some poor areas such as Africa, the Middle East, and South America.

The absorbent layer of second-generation diapers is mainly SAP paper & pulp core, which has a relatively fast instant absorption speed, but its thickness, conductivity and absorption strength still have certain limitations, which can easily lead to uneven absorption, faults, lumps, and severe cases may lead to urine leakage and diaper rash;diapers like this are more popular in Africa, Southeast Asia, Russia and other places.

The absorbent layer of the third-generation diapers is SAP paper core. Compared with the second-generation diapers, they are thinner, more close-fitting, less prone to reverse osmosis, and have better diversion and water-locking capabilities. Therefore, the third-generation diapers are widely used, as in China, all It has become more and more popular in Russia, Southeast Asia, Europe and the United States;

If you want to get more information, please contact us as soon as possible~